Client profile and key challenges

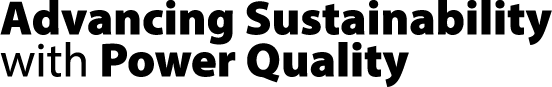

Dynaplast Indonesia is a prominent manufacturer specializing in high-precision plastic packaging solutions, serving diverse industries with cutting-edge production facilities. Their operations rely heavily on advanced equipment, including robotic systems, blowers, and compressors, ensuring efficiency and quality in their manufacturing processes.

However, the extensive use of these non-linear loads introduced significant harmonic distortion into the electrical system. This led to critical challenges, including high temperatures in electrical cables due to harmonic currents, risking insulation damage and potential fire hazards. Additionally, harmonic interference reduced equipment efficiency and increased maintenance costs, requiring frequent interventions to mitigate overheating and maintain operational reliability.

Solution

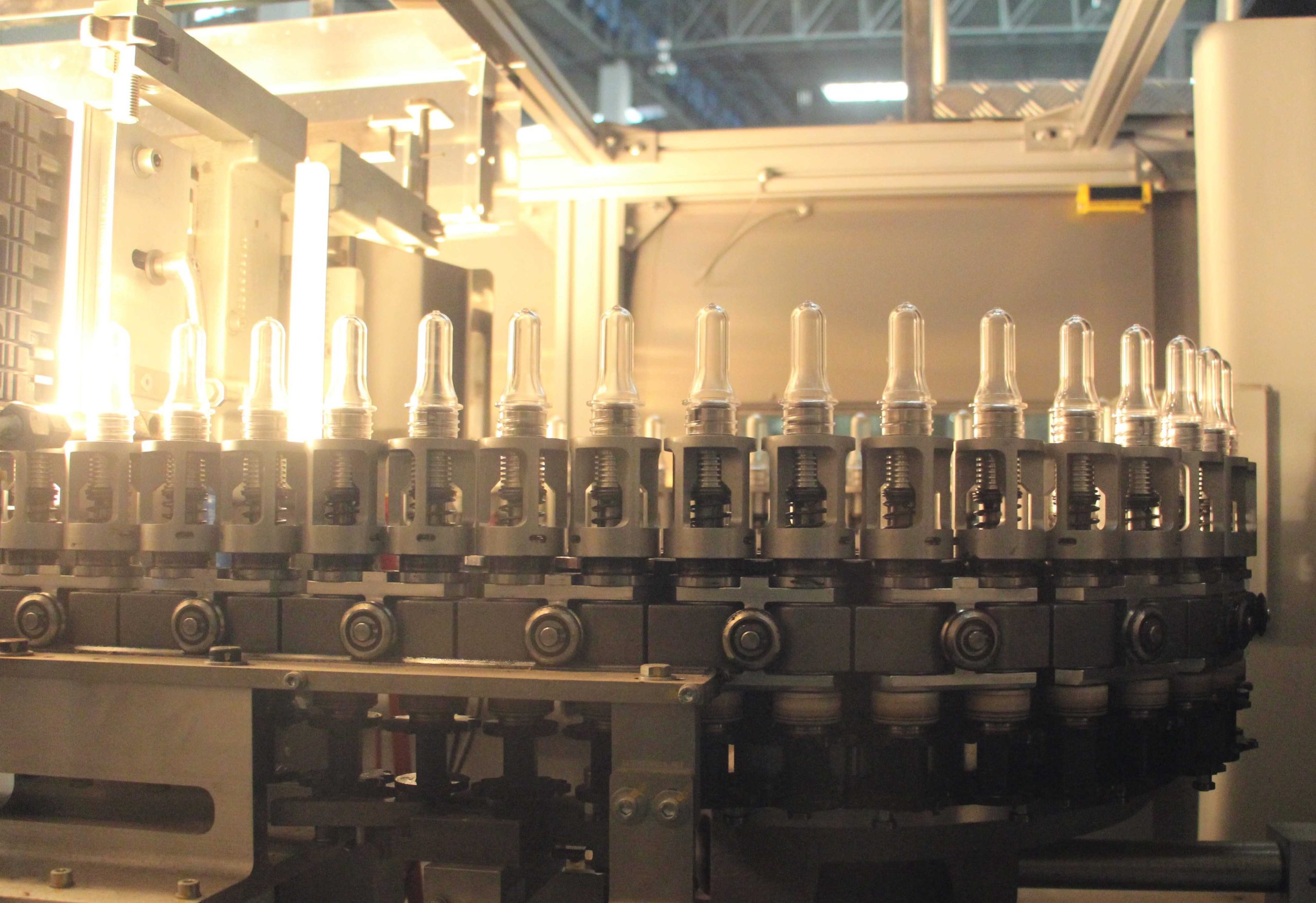

To mitigate the power quality challenges faced by Dynaplast Indonesia, Oscorp Elektrik Indonesia deployed its advanced PQactiF active harmonic filter. This state-of-the-art solution effectively eliminates harmonic distortion, reduces thermal stress on cables, and optimizes overall power system performance.

By addressing the root causes of harmonic-induced overheating, PQactiF safeguards critical manufacturing equipment, including robotic systems, blowers, and compressors, ensuring operational reliability and efficiency.

The implementation of PQactiF has resulted in a robust, energy-efficient electrical infrastructure that minimizes maintenance demands, mitigates the risk of cable insulation failure, and supports uninterrupted, high-precision manufacturing processes.

For inquiries, product demonstrations, or to discuss your power quality needs, please don’t hesitate to contact us.

Whatsapp for further info Download White Paper and Technical Data